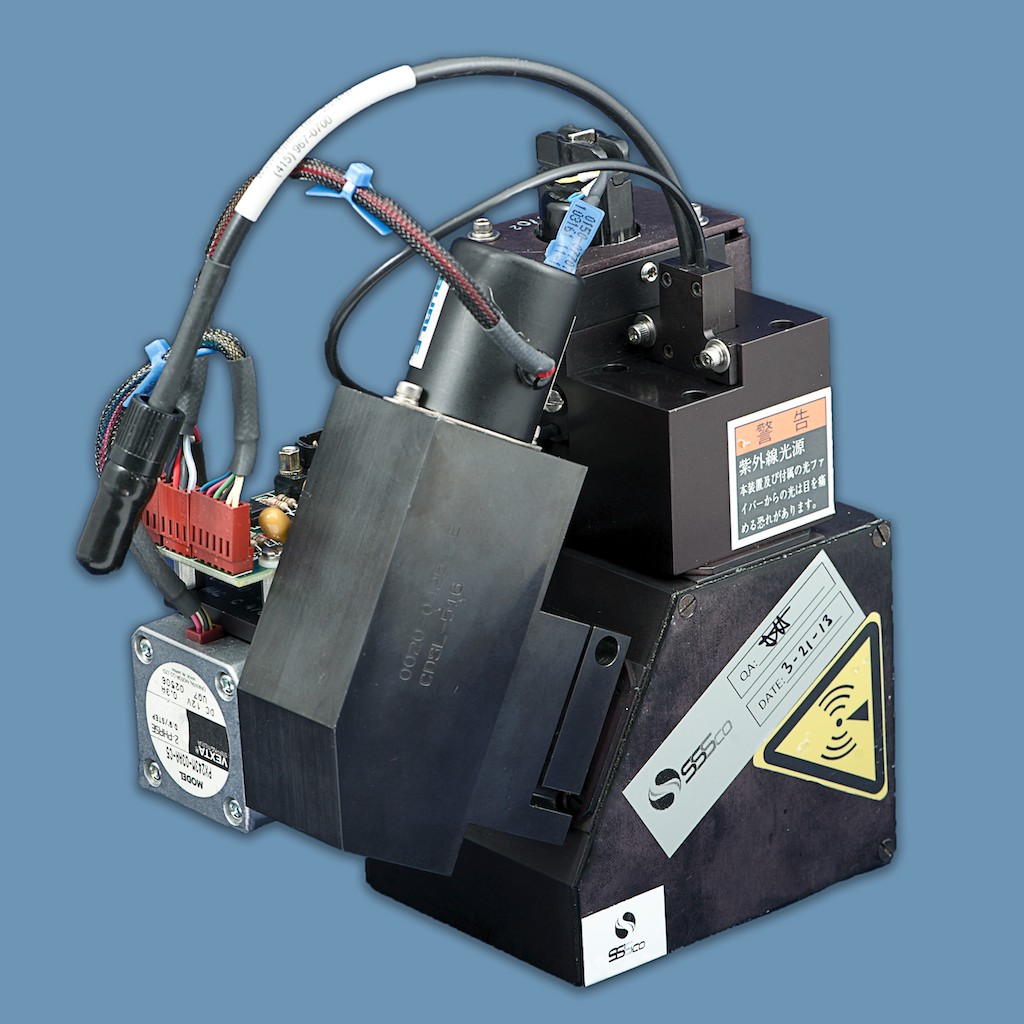

Monochromator Refurbishment

SSSco provides full refurbishment for Monochromators used by AMAT Etch systems.

Our Refurbishment process includes:

- Photo Multiplier Tube & Power Supply

- Fiber Optic Cable

- Stepper Motor

- Calibration lamp

- Holographic Grating

- Mechanical assembly

![]()

Monchromator units should provide years of trouble free service but can degrade over time. This causes errors due to stepper position loss and can lead to over-etch or under-etch, missed endpoint or failed calibration (greater than 20 angstroms). Calibration and alignment is critical to accurate operation and repeatable process results. SSSco has developed processes and procedures to restore the units to like-new condition.

![]()

After refurbishment, monochromator units are calibrated to ensure that the error rate is 1 angstrom, the lowest measurable rate by the endpoint computer. Each units is then put through a reliability test of several hundred alternating endpoints of different wavelengths on our custom endpoint test system. Finally, calibration is checked again to ensure that the 1 angstrom calibration error remains.

Typical turn around time for this service is 1 week or less. We may have units available for rapid exchange.

| Description | OEM # | SSSco # |

|---|---|---|

|

Monochromator, P5000 (Short Fiber Optic Cable) |

AABA-09935 |

|

|

Monochromator, Centura (Long Fiber Optic Cable) |

AABA-10556 |

|

|

Monochromator, Centura (Non-Ceramic Socket, Updated UV Socket) |

AABA-14157 |