Neslab III Heat Exchanger Remanufacturing

SSSco provides remanufacturing of Neslab® III heat exchangers used on Endura® 5500 PVD systems. We service the original and updated digital controller model.

Key Benefits of remanufacturing

-

Fully refurbished, not just repaired

Fully refurbished, not just repaired - Fully tested

- Warrantied for twelve months

Remanufacturing Tasks

- Flow sensors rebuilt

- Pump fully refurbished

- New hoses installed

- DI canister replaced

Complete remanufacturing process

-

Initial evaluation of unit, mechanical and electrical check.

Initial evaluation of unit, mechanical and electrical check. - Pump is fully rebuilt or replaced including impeller and seal kit.

- Float switch is removed, cleaned and inspected.

- Flow sensors are disassembled, cleaned and rebuilt.

- All rubber hoses are replaced.

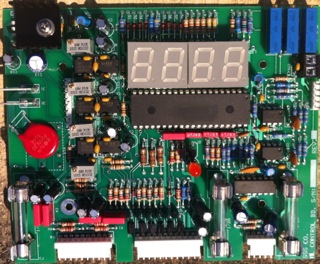

- Electrical interface board is repaired, if necessary.

- Minimum 12 hours of testing, proprietary QA process

SSSco can provide all parts to repair Neslab® III including:

- Replacement control board

- DI sensor

- DI canister

- Hoses

- Tank

- Pump