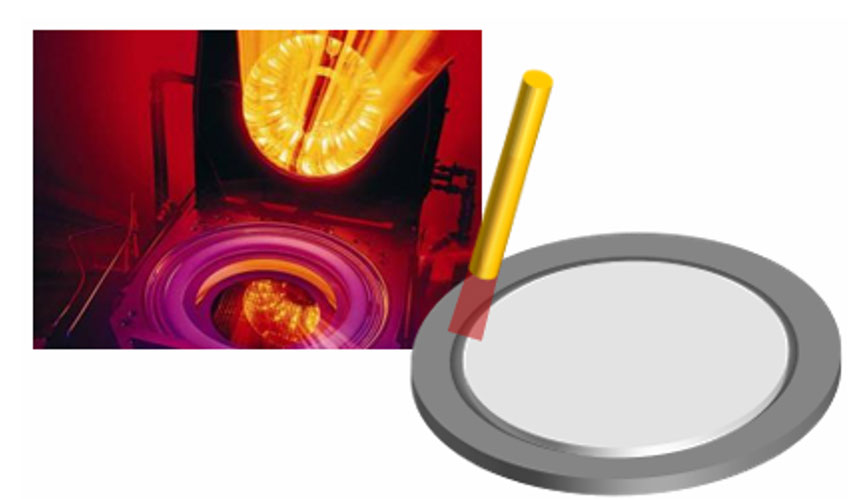

Edge Zoom Wafer Tracking System

Precision Insight at Process Temperature

EPICREW’s Edge Zoom system provides advanced, in-situ monitoring of wafer position during high-temperature processing. With gap and motion analysis capabilities, Edge Zoom gives engineers the data they need to understand, debug, and optimize process performance. Its integration with factory data networks makes it a powerful tool for quality, traceability, and tool performance improvement.

What Edge Zoom Does

- Captures wafer position in real-time during high-temperature process steps

- Measures the gap between wafer edge and susceptor pocket with high precision

- Quantifies susceptor wobble and maps max/min gap positions across the wafer

- Tracks actual susceptor rotation speed

- Outputs data into SQL database with network access for analysis and traceability

Benefits & Applications

Immediate insight into wafer position and motion anomalies

Enables predictive maintenance and root cause analysis

Helps tune processes for uniformity and repeatability

Supports continuous improvement initiatives with reliable, structured data

Why Choose SSS Co

- Industry Expertise – Our engineering team builds tools that meet real fab challenges with precision and speed

- Quality Without Compromise – Every Edge Zoom system is tested and verified to meet exacting standards

- Global Trust – From development labs to high-volume fabs, customers rely on SSS Co for intelligent process insight